Pool Surfaces

The swimming pool surface is the heart of the pool and considered by many as the most important decision to make in the pool renovation/building process. The pool interior will not only affect the final water colour but will also change the whole image of the yard and surrounds.

With almost 4 decades of experience within the pool surface industry, your pool interior is in the right hands.

At Ero Pools, we try to keep the process simple. We offer expert advise on the final decision you will make ensuring the client is left with a durable, smooth and timeless pool surface. There are many factors that affect the pool interior like the colour of the coping/waterline, amount of trees around the pool area, amount of sun the pool will receive, widths and depths of the pool, quality of the existing pool structure and more.

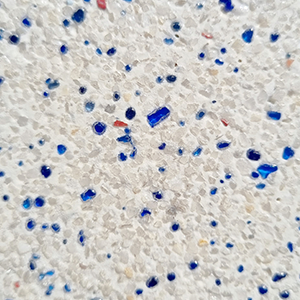

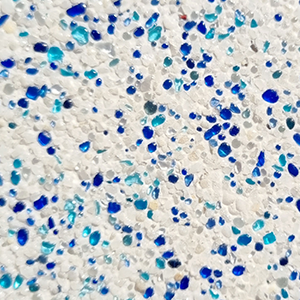

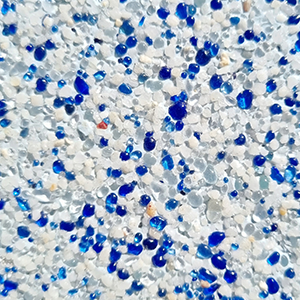

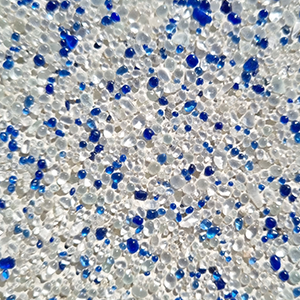

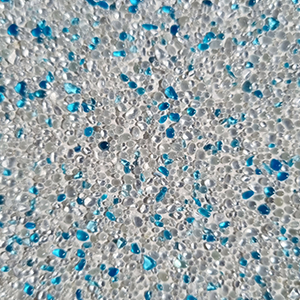

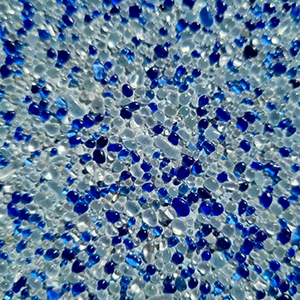

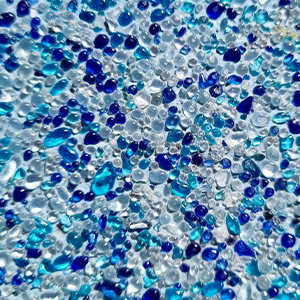

Pool Surface TypesSwimming pools are engraved into Australian culture unlike anywhere in the world. Most properties in NSW now have a pool presence in their yards, and this culture has been in place for over 50 years. Looking back at many of the pools we have installed/renovated/built, one aspect of the pool has stood the test of time. Pebblecrete based pool renders. Pebblecrete based pool renders are the strongest and most cost effective coating for a concrete swimming pool. Many other surface types have come and gone within the industry yet pebblecrete still outlasts them all. Its a simple and effective method of high quality New Zealand pebbles mixed with premium pool classified cements and additives to give a rock solid product used all across the world. Obselite methods of pool coatings like Quartz, Marblesheen and pool paints have proved to be unsafe, poorly durable and ineffective, paving the way for the pebblecrete industry to take over the surfacing market. Over the years a new additive to the pebble surfaces has emerged and has helped pebblecrete evolve into a modern and ultra smooth finish. The addition of small, rounded glass beads to the mix has helped the product become smoother and the wide range of bead colpours helps darken the finish and match it to countless numbers of mosaic tiles. The general rule is that the more glass beads are added, the smoother the finish and the more it will shimmer/sparkle as the sun reflects through it. It is also slightly more stain resistant as opposed to the porous pebbles. So for your new pool surface, insist on pebblecrete, pebblecrete, pebblecrete! | Types Of Pebblecrete SurfaceStandard option The standard option in pebblecrete is made with a matrix of generally 90-100% New Zealand premium 1-2mm pebble mixed with up to 10% glass beads. Mid-ranged option The mid-ranged option is made with a matrix of approx 60% New Zealand premium 1-2mm pebble and approx 40% glass beads. Coloured oxides can also be added to this range to enhance the colour of the cement. Premium option The premium option is made with a matrix of approx 90% glass beads and 10% New Zealand premium 1-2mm pebble. Coloured oxides can also be added to this range to enhance the colour of the cement.

|

With almost 4 decades of experience within the pool surface industry, your pool interior is in the right hands.

FAQ

| What is the smoothest pebble surface? | All the pebble surfaces we use are smooth underfoot and nothing like the old conventional pebblecrete, however the more glass beads in the mix the more ultra smooth the finish will be. |

| Are all pebblecrete surfaces the same to maintain? | No. The lighter colours which contain a white pebblecrete base are lower maintenance as opposed to the blue pebblecrete base. This is due to the pigments and oxides used to colour the cement which is slightly more sensitive to chemical negligence. You can find info on how to minimise chemical damage on our Pool equipment page under chemical dosing (link here to pool equipment page) . |

| Why do the same colours on the website look different? | Many factors affect the final water colour of your pool. Things like the weather (sunny/overcast), pool structure ( water depths/widths) and positioning (shade/full sun), amongst others, all have bearings on the final outcome of the water colour. |